Vlaming Sub-basin CO2 Storage Project

Page last updated:8 April 2016

Overview

As part of the Australian Government's National CO2 Infrastructure Plan (NCIP), Geoscience Australia undertook a comprehensive study in the offshore Vlaming Sub-basin to provide new pre-competitive data and information on potential CO2 storage solutions offshore Perth, Western Australia.

The Vlaming Sub-basin is a Mesozoic depocentre within the southern Perth Basin located about 30 km west of Perth. It covers an area of approximately 23,000 km2 and contains up to 14 km of sediments. The basin lies close to industrial sources of CO2 emissions in the Perth area and contains a number of reservoir-seal pairs potentially suitable for CO2 storage. According to a previous assessment by the Carbon Storage Taskforce in 2009, the Early Cretaceous Gage Sandstone and the overlying South Perth Shale are the most prospective reservoir-seal pair for CO2 storage in this basin with potential to store up to 1100 million tonnes of CO2. The Geoscience Australia study focused on critical aspects the CO2 storage potential of the Vlaming Sub-basin that were not fully explored in the past, which included reservoir heterogeneity, seal quality and integrity and practical storage capacity.

Reservoir and seal properties

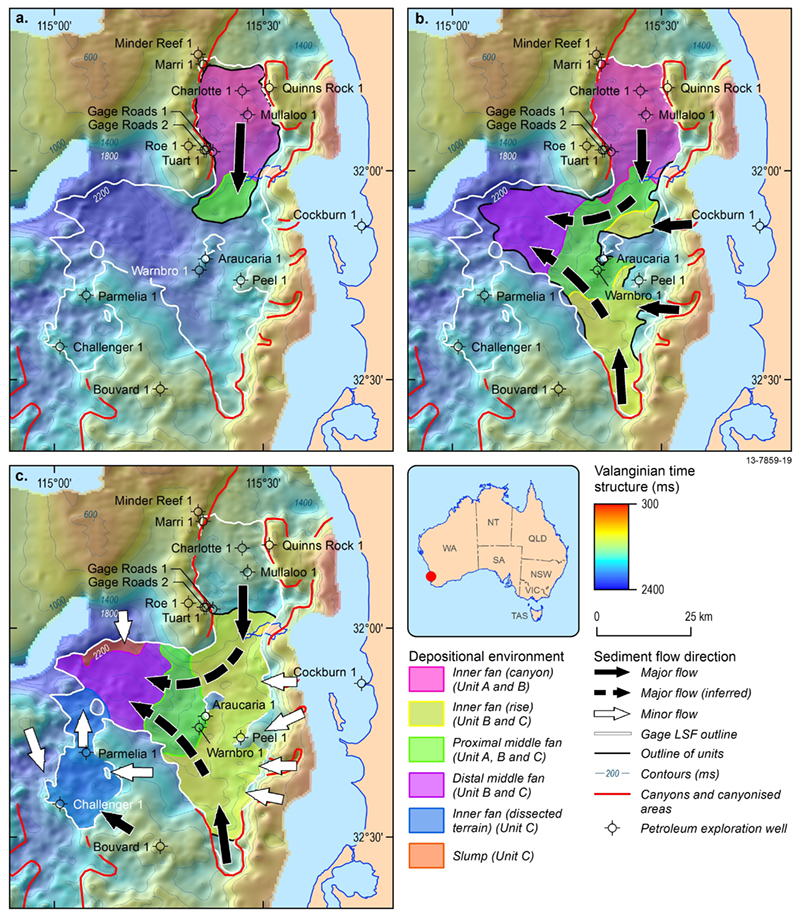

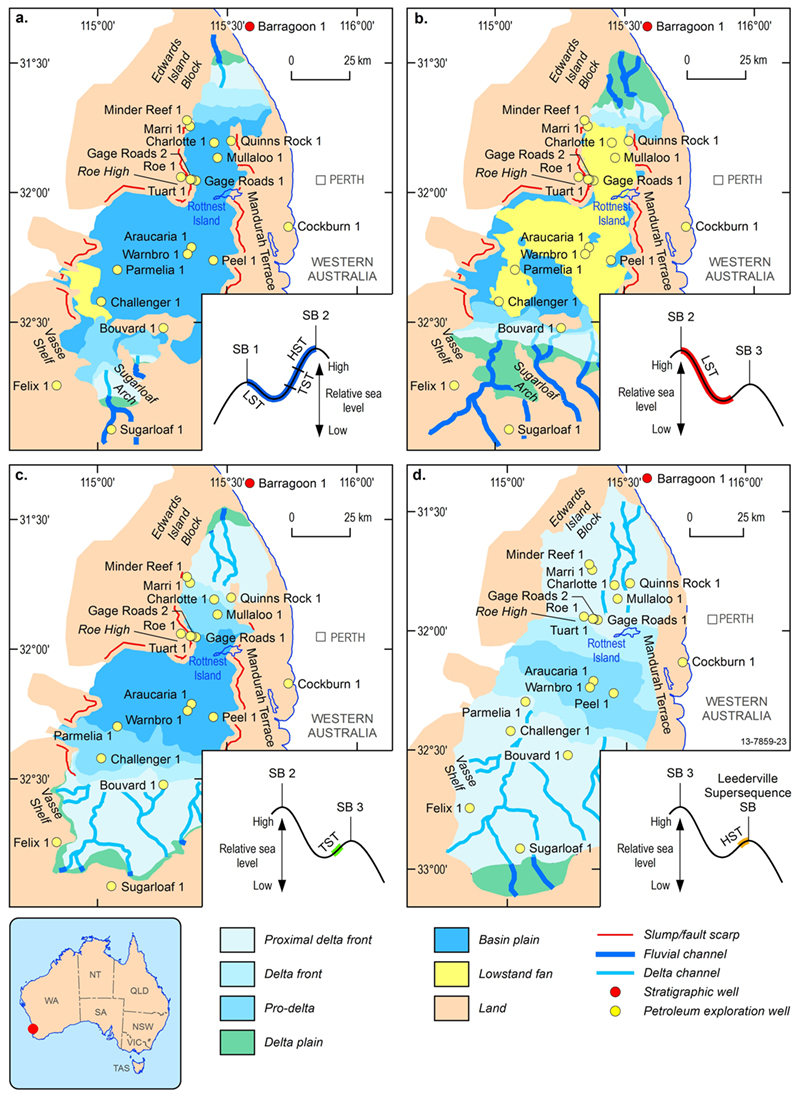

Understanding the variability of reservoir properties (e.g. porosity and permeability distribution) is essential for accurate estimation of the reservoir capacity. The study documented changes in depositional environments during deposition of the Gage Lowstand Fan (LSF). Understanding the evolution of the Gage LSF (Figure 1) based on seismic facies analysis, led to characterisation of the reservoir heterogeneity. Similarly, characteristics of the South Perth Shale seal were derived from paleogeographic reconstructions based on seismic facies mapping (Figure 2), which provided information on the distribution of the sealing lithologies.

Seal integrity

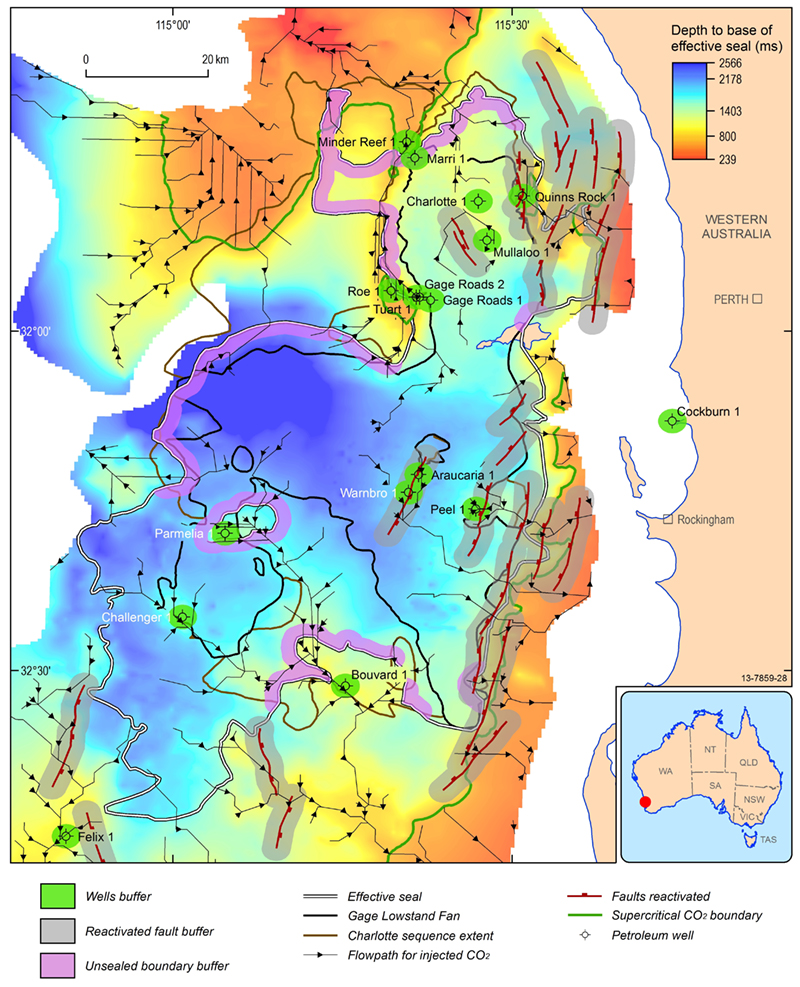

Good seal integrity is essential for utilising all available pore space in a reservoir. While the study showed that seal quality is adequate over most of the Gage reservoir, seal integrity is a key problem in some areas. The study identified faults with signs of reactivation or seepage in seismic reflection data (Figure 3) and analysed high-resolution swath-bathymetry data for evidence of present-day fault reactivation. Additionally, Fluid Inclusion Stratigraphy (FIS) and Grains with Oil Inclusions (GOI) were used to evaluate the effectiveness of the seal. 3D modelling of fault behaviour, undertaken in collaboration with CSIRO, showed which faults are more likely to be reactivated in response to CO2 injection.

Over a large area in the Vlaming Sub-basin the Gage reservoir overlies older reservoir units. The connectivity between the Gage reservoir and these older units is poorly understood. However, if they are connected, the injected CO2 could potentially migrate into these units. The most widespread reservoir unit beneath the Gage LSF is the Charlotte Sandstone. We have mapped the distribution of the Charlotte Sandstone and delineated areas, where it is not sealed by the South Perth Shale. If the CO2 is injected into Gage LSF close to these unsealed areas, it may find an escape pathway through Charlotte reservoir (Figure 3).

Practical storage capacity

The study confirmed that the Gage LSF has excellent reservoir qualities and the overlying South Perth Shale seal has a good sealing capacity. However, the ability to use the available pore space in the Vlaming Sub-basin is controlled predominantly by the seal integrity.

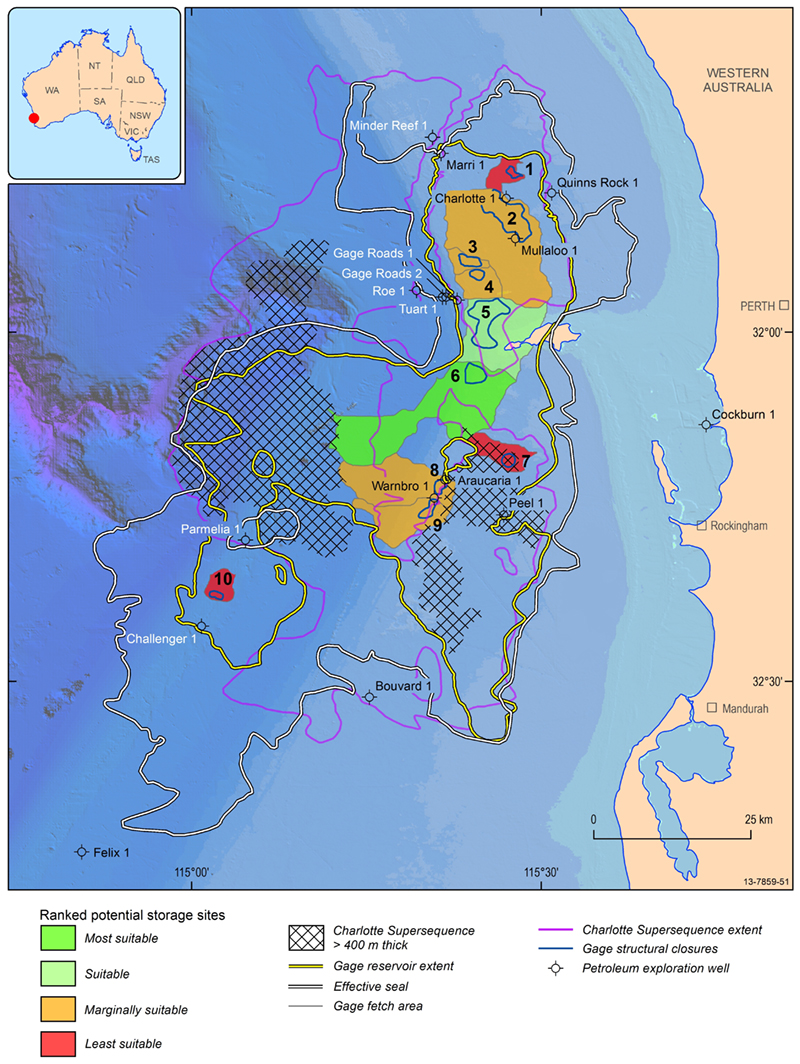

Geological modelling and spatial analysis identified areas potentially suitable for CO2 storage (Figure 4). Selection of suitable storage sites was guided by a number of factors: quality and thickness of the reservoir, quality and integrity of the top seal, location of the supercritical CO2 boundary and predicted migration paths for the injected CO2. The ten largest fetch areas and structural closures from the migration path modelling were analysed and ranked for their CO2 storage suitability.

The most prospective areas for CO2 storage in the Gage reservoir have been identified (Figure 4), an overall storage capacity of 118 million tonnes of CO2. The new storage capacity estimate for the whole Gage reservoir at P90 is 126 million tonnes; at P50 is 493 million tonnes; and at P10 is 1360 million tonnes. The Charlotte Sandstone has been identified as another reservoir potentially suitable for geological CO2 storage. Based on seismic mapping and the preliminary geological model, the storage capacity of the Charlotte Sandstone reservoir at P90 is 505.6 million tonnes; at P50 is 1983 million tonnes; and at P10 is 5453 million tonnes. Due to the lack of data for this stratigraphic interval, no potential storage sites were defined in the Charlotte Sandstone.

Overall, the study confirmed the suitability of the Gage reservoir for long-term storage of CO2 and provided a more accurate delineation of suitable storage sites. At the same time, it highlighted the importance of containment and indicated that the practical storage capacity of the Vlaming Sub-basin is potentially significantly smaller than previously expected.