Diamond

Page last updated:17 May 2018

Introduction

When the word 'gemstone' is heard, most people think first of diamonds, famous for their ability to sparkle so beautifully in light. The ancient Greeks believed that diamonds were splinters of stars fallen to the Earth. Until the 15th century only kings wore diamonds but in 1477 that changed when the diamond took on a new role. The Archduke Maximillian of Austria had a diamond set in a ring which he presented to Mary of Burgundy, thus beginning the tradition of giving a diamond as a promise for marriage.

Properties

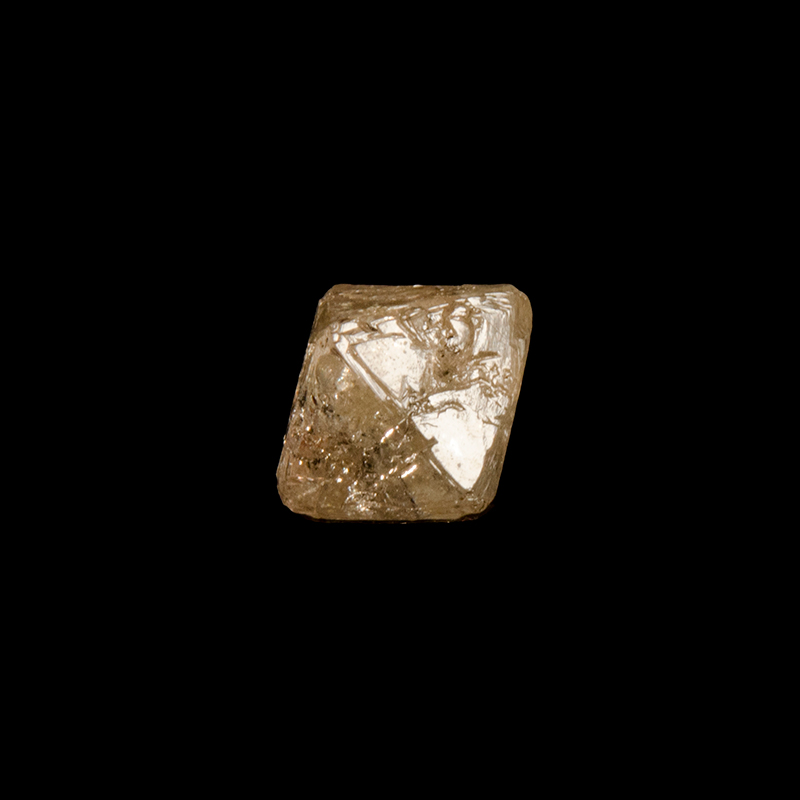

Diamonds are made of pure carbon in a crystallised form, although they often contain inclusions of other minerals and are an excellent refractor of light. Diamonds are usually clear, although they have a range of colours, such as are pink, golden or blue.

Diamonds rate a 10 on the Mohs scale of hardness (from 1 - 10). This makes diamond the hardest natural mineral on Earth. Diamond has a very high melting point of 4000°C which is 2.5 times hotter than the melting point of steel.

The Properties of Diamond

Chemical Symbol | C (Carbon) |

|---|---|

Ore | Kimberlite and lamproite volcanic pipes |

Relative density | 3.5 g/cm3 |

Hardness | 10 on Mohs scale |

Uses

Since the early 1900s diamond has been used to grind and shape very hard metal alloys, such as tungsten carbide, for use as machine tool tips. Diamond polishing powders and compounds are used for fine finishes on optical surfaces, jewel bearings, wire drawing dies, cutting tools, aircraft engine components and many other items made from metals, ceramics, plastics and glass. Diamond grit and powder-impregnated rock drilling bits are used in oil, gas and mineral exploration and production; foundation testing for dams, buildings and other construction; masonry drilling; and concrete test sampling. Circular metal saw discs with a diamond-impregnated edge also are used to cut roads, grooves in airport runways, concrete, building stone, bricks and shapes for furnace linings.

Diamond machine tools are used in the electrical and engineering industries, such as car, aircraft and ship building. Very thin diamond-impregnated saw blades are used to slice brittle metals and crystals for use in electronics. Knives in the home can be sharpened using 'steels' impregnated with diamond powder.

| Use | Description |

|---|---|

Jewellery | Diamonds of good quality are used in jewellery (rings, earrings, necklaces, brooches and bracelets). |

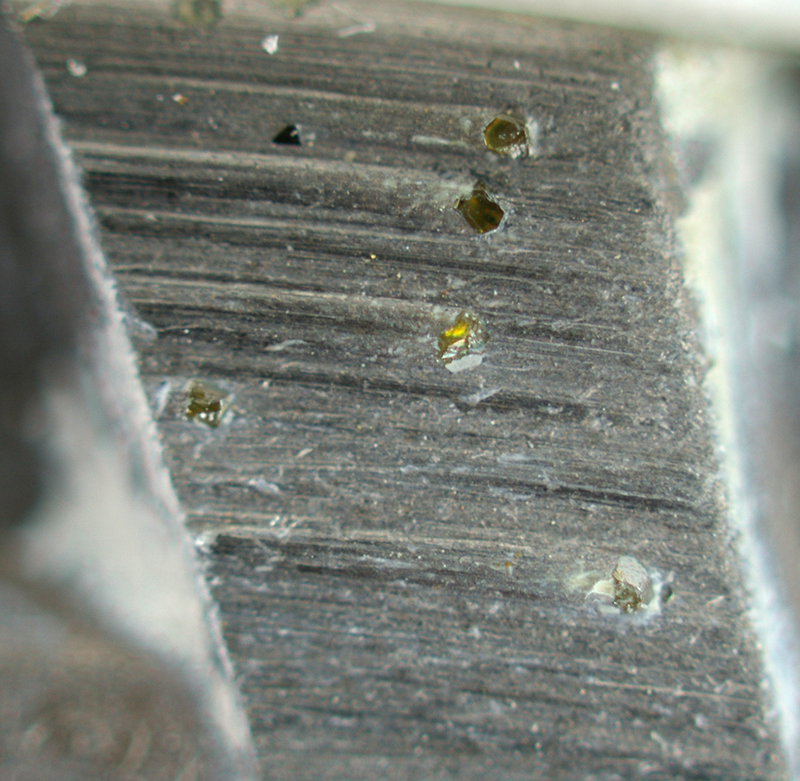

Industry | Very small and poor quality stones are called 'industrial diamonds' and are used as the abrasive material on cutting wheels and drill bits, machine bearings, glass cutting implements and grinding and polishing powders. |

History

The first use of diamond may have been as a talisman or charm by prehistoric humans. Diamond was highly prized as a gem stone in ancient Egypt, Babylon, Mesopotamia and India. The Romans used it to carve cameos from stone and exported diamond to China for cutting jade and drilling pearls. Large diamonds were used by kings, queens and other nobles as symbols of wealth and rank. The Regent diamond, found in India, in 1701, became part of the French Crown Jewels until stolen in the French Revolution and eventually set in the hilt of Napoleon's sword.

3000 year old records from India indicate that diamonds were used in two ways - for decoration and as a talisman to ward off evil or provide protection in battle. Alexander the Great brought diamonds from India to Europe in 327 BC. Alluvial gold miners in Brazil found what they described as 'curious pebbles' in 1725, which were subsequently identified as diamonds. Alluvial diamonds were discovered in 1859 in South Africa and in 1869 mining of the hard rock sources of diamonds started at Kimberley, the capital of the Northern Cape Province of South Africa.

The biggest and most precious diamond ever found was discovered in 1905 by Frederick Wells, Manager of the Premier Diamond Mine in South Africa. As he walked along the edge of the open pit mine he saw something glinting in the sun so he dug it out using his pocket knife. What he found was a diamond crystal as big as his fist, more than three times larger than the biggest diamond ever seen! It weighed 3,106 metric carats or about 620 grams and was perfect - colourless, transparent and flawless. Called the Cullinan Diamond, after Thomas Cullinan (founder of the Premier Diamond Mining Co.) it was bought by the Transvaal government and presented to King Edward VII on his 66th birthday. Then in 1908 it was entrusted to the famed House of Asscher in Amsterdam for cutting. Asscher spent many anxious weeks planning how to cleave the gem. If his calculations were not correct, the priceless diamond could shatter into a million pieces! But the gem was cleaved perfectly, into 105 faceted diamonds. The largest of these is the Cullinan I, which is set in the British Royal Scepter. The Cullinan II is set in the base of Britain's Imperial State Crown. Both pieces are housed in the Tower of London, along with Britain's other Crown Jewels.

Formation

Diamond occurs naturally but is extremely rare compared to other minerals. Diamond is thought to form 150 km to 200 km below the Earth's surface, where high temperatures (1050°C - 1200°C) and pressures (45 kilobars - 55 kilobars) allow it to crystallise. The diamonds may then be picked up by hot molten rock (magma) and transported upwards as the magma intrudes up into the Earth's crust. These intrusions form narrow cylindrical bodies called 'pipes' and only a very small proportion have significant diamond content. When pipes are eroded, liberated diamonds may accumulate in alluvial deposits. Diamonds may be found far from their source as their hardness allows them to survive multiple episodes of erosion and deposition.

The quality of diamonds can be split broadly into gem, near gem, industrial and boart categories. In rare cases 90% of diamonds in a deposit are of gem quality; but most economic deposits contain 20% to 40% gem-quality diamonds.

Large quantities of industrial-grade synthetic diamonds are made in several countries. It is also possible to make gem-quality diamonds.

Resources

For hundreds of years India was the world's source of diamonds. However, as that supply started to dwindle, there were smaller finds in Borneo and Brazil. The discovery of a large diamond deposit in South Africa in the mid-1800s helped to meet the world's increasing appetite for these gems. Today, diamonds are also mined in South Africa, Botswana, the Democratic Republic of Congo, Australia, Canada, Zimbabwe, Namibia, Angola, throughout many countries in western Africa and Russia.

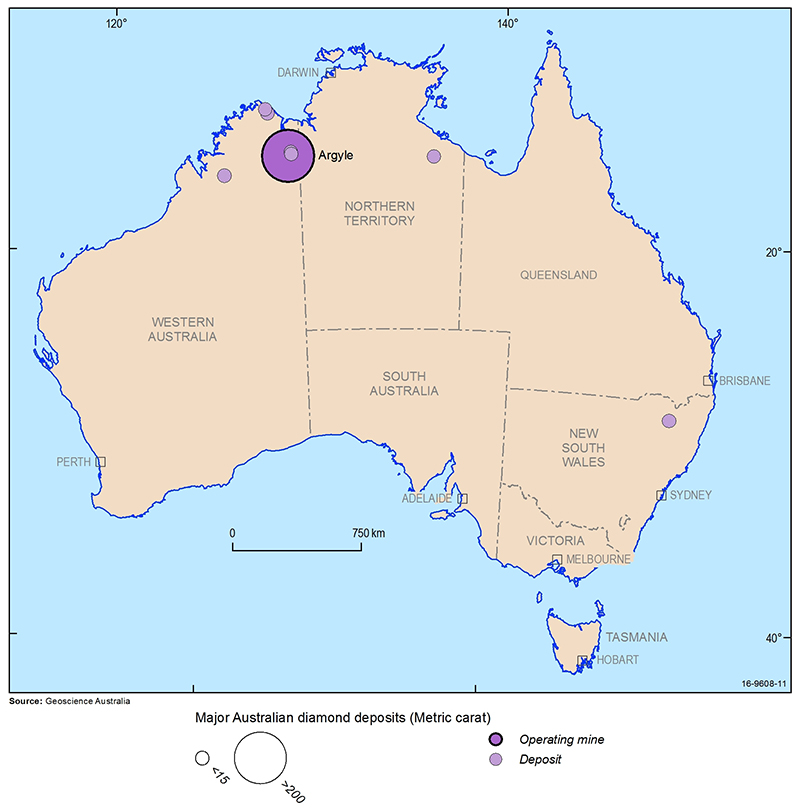

Diamonds in Australia were recorded in the Bathurst area, New South Wales in 1851. Significant quantities also were mined from alluvial deposits at Copeton and Bingara, near Inverell in north-eastern New South Wales, from 1867 to 1922 and minor production resumed at Copeton in 1997, but has since stopped. Numerous minor occurrences of diamond have been recorded elsewhere in Australia.

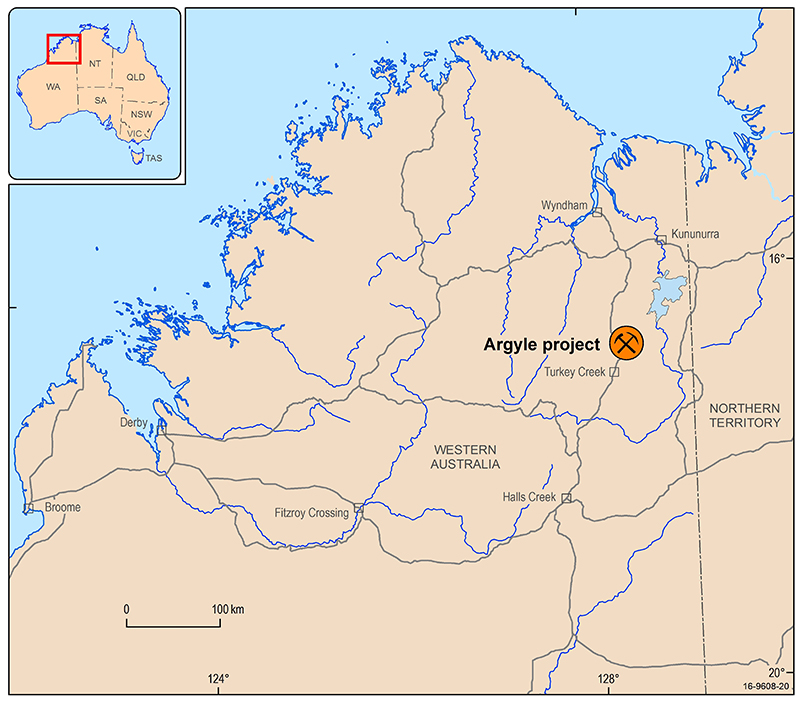

Creek sediment sampling and other exploration techniques in the early to mid-1970s led to the discovery of 23 diamondiferous but low-grade pipes at Ellendale in 1976 and the Argyle deposit in 1979. Shark cages were used in the late 1980s to protect scuba divers against crocodiles while they sampled diamonds (eroded from land) from the seabed off river mouths in the north-east Kimberley region. Small numbers of gem-quality diamonds have since been recovered using an airlift drill attached to a boat.

It was not until the late 1970's that geologists found the Argyle pipe in the remote Kimberley area of Western Australia: the richest diamond deposit in the world. Argyle is the world's largest volume producer of diamonds, supplying a third of the world's diamonds every year and since the late 1980s, over 90% of the world’s pink diamond supply has come from Rio Tinto’s Argyle mine. The Argyle deposit contains a large proportion of the world's economic diamond resources and has some of the highest diamond grades in the world. Argyle sells 100% of its product direct to the world market. The majority of Argyle’s diamonds are sold as “rough” or uncut diamonds.

Relatively small resources of alluvial diamonds were worked nearby in Smoke Creek (Argyle Alluvials) and the Bow River Mine. A number of small diamond 'pipes' with a much higher proportion of gem-quality diamond than Argyle have been mined at Merlin in the Northern Territory and Ellendale in the west Kimberley region, both of which are currently not in operation..

About 70% of the world market for rough diamonds is controlled by the London-based Central Selling Organisation (CSO). The CSO was formed in 1934 in response to cyclical price slumps and the total closure of diamond mines in South Africa during the Great Depression.

Mining

Approximately 250 tonnes of ore must be dug from the ground to produce a one carat (200 milligram) polished diamond of gem quality. Diamond mines are open-cut or underground. The ore is blasted with explosives then loaded onto trucks for transport to a processing plant where it is cleaned and sorted. Large-scale, open-pit mining was initially used to extract diamond ore at Argyle. The mine is now a large scale underground block cave operation. Broken ore is crushed to fragments measuring around 18 millimetre or less. Any diamonds larger than 18 millimetres would be broken. Extraction of these large diamonds is uneconomic as statistical sampling indicates they are extremely uncommon and of poor quality. The crushed ore is washed in large rotating drums called scrubbers and fed to gently sloped, vibrating, double decked, slotted screens which sieve out three size fractions.

Alluvial deposits in Australia, at Smoke Creek and Bow River near the Argyle mine, were strip mined by excavator and either trucked directly to a processing plant or loaded into a mobile screening plant to remove the larger rocks before trucking to the plant. Crushing is not needed, otherwise processing is very similar to that described below. Reject material from the plant is returned to backfill the mine site and the land surface is then comprehensively rehabilitated.

Processing

Finely ground ferrosilicon is mixed with water to make a thick, dense liquid (heavy media). When added to this liquid the lighter unwanted rock of the screened ore is more buoyant than the heavier diamonds. This buoyancy difference is used to separate the diamonds by pumping the liquid and its contents into downward-angled, metal cones (cyclones) in a descending spiral flow. The unwanted light material exits the top of the cyclone and diamonds and other heavy minerals exit at the bottom.

At the diamond recovery plant the heavy minerals pass through radial X-ray sorters, developed to cope with the unusually high diamond content of the Argyle ore. Diamonds, unlike most of the other heavy minerals, fluoresce (glow) when exposed to X-rays and can be identified for removal from the flow of concentrate. They are washed in acid to remove any coatings and sent to Perth for shipment to Antwerp. there they are sorted, valued and marketed, with the more valuable pink and, sometimes, red diamonds returned to Perth for further sorting and cutting. The majority of all rough diamonds produced in the world, including those from Argyle, are now cut and polished in India.

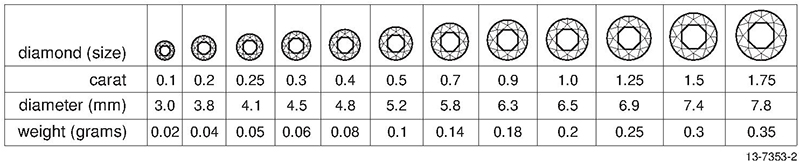

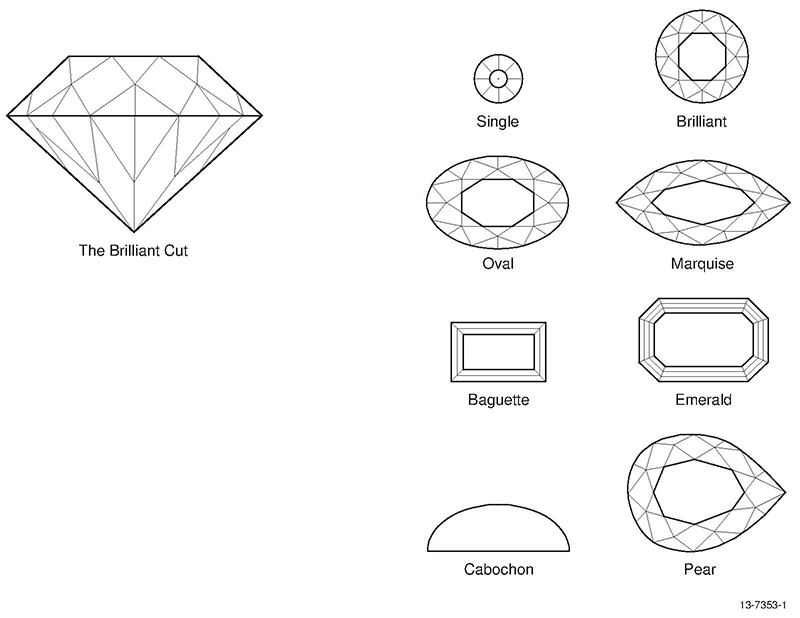

Sorting of rough diamonds by hand begins with separation into about 15 different size groups by sieving. Highly skilled sorters grade these groups into about 7000 different categories according to crystal shape, colour and quality (extent of flaws, impurities and inclusions). In each group the better diamonds are classified as gems or near gems and the poorer ones as industrial. Automatic machine sorting on the basis of size, colour and shape can also be used. Cutting and polishing of a rough diamond may start with 'cleaving' (splitting) along its grain (weaker crystal planes) to divide it into smaller pieces or remove flaws and impurities. Lasers or very thin circular metal blades impregnated with diamond dust are used to saw across the grain of diamond. A cleaved or sawn diamond is roughly shaped or 'bruted' by grinding its edges off with another diamond. The end result resembles the shape of a spinning-top.

A horizontal spinning metal wheel (scaife) covered with diamond dust is used to grind and polish flat faces (facets) on bruted diamonds. To obtain the maximum gem brilliance the facets must be the right size and at the correct angles to each other. The 'brilliant' cut is the most common for modern jewellery diamonds and consists of 57 facets. Cut and polished diamonds are graded into numerous categories based on clarity, colour, cut and size.

Usually, more than 50% of a rough diamond is lost in cutting and polishing, or up to 80% if it is flawed or misshapen. One hundred and five stones were cut from the largest diamond ever found (about the size of a human fist), called the Cullinan diamond (from South Africa), but they represent only one third of the original crystal weight.

In the past, natural diamond quality was subdivided into gem, near-gem and industrial categories, however recent developments within the diamond industry has resulted in almost all natural diamonds being used for jewellery. The United States Geological Survey (USGS) reports that only 3% of industrial diamonds are non-synthetic.